Drum Dryer

In the center of the drum dryer can be avoided to increase the dispersing mechanism, into the drying cylinder body of wet materials by the cylinder wall of the coping repeatedly copied, thrown down, in the process of falling down by the dispersing device broken into fine particles, than the area increased substantially, and the hot air fully contact, drying.

Product Description

Widely used in alfalfa grass drying, alcohol dregs drying, straw drying, wood chips drying, marigold drying, shavings drying, ginkgo biloba drying, herbal medicine drying, beer dregs drying, liquor dregs drying, potato starch dregs drying, cassava dregs drying, barley malt drying, melon seeds drying, sugarcane dregs drying, hawthorn drying, canola cake drying, vegetable drying, etc., the thermal efficiency of up to 80%, significantly higher than the domestic equipment of the same kind. The machine is mainly composed of rotary body, rotating body, rotating body, rotating body and rotating body.

The machine is mainly composed of rotating body, lifting plate, transmission device, supporting device and sealing ring and other components. The dryer is a slightly inclined cylinder with the horizontal direction, the material is added from the higher end, the high temperature hot flue gas and the material flow into the cylinder, with the rotation of the cylinder, the material is run to the lower end due to the action of gravity. In the inner wall of the cylinder is equipped with a coping board, the material is copied up and sprinkled down, so that the contact surface of the material and the airflow increases, in order to improve the drying rate and promote the material forward. The dried product is collected from the lower part of the bottom end.

Technical Parameters

| Model | Gradient(%) | Rotation Speed(r/min) | Feed-in Gas Temperature(^c) | Power(kw) | Output(t/h) | Weight(t) |

|---|---|---|---|---|---|---|

| 600*6000 | 3-5 | 3-8 | <=700 | 3 | 0.5-1.5 | 2.9 |

| 800*8000 | 3-5 | 3-8 | <=700 | 4 | 0.8-2.0 | 3.5 |

| 800*10000 | 3-5 | 3-8 | <=700 | 4 | 0.8-2.5 | 4.5 |

| 1000*10000 | 3-5 | 3-8 | <=700 | 5.5 | 1.0-3.5 | 5.6 |

| 1200*10000 | 3-5 | 3-8 | <=700 | 7.5 | 1.8-5 | 14.5 |

| 1200*12000 | 3-5 | 3-8 | <=700 | 11 | 2-6 | 14.8 |

| 1500*12000 | 3-5 | 2-6 | <=800 | 15 | 3.5-9 | 17.8 |

| 1800*12000 | 3-5 | 2-6 | <=800 | 18 | 5-12 | 25 |

| 2200*12000 | 3-5 | 1.5-6 | <=800 | 18.5 | 6-15 | 33 |

| 2200*18000 | 3-5 | 1.5-6 | <=800 | 22 | 10-18 | 53.8 |

| 2200*20000 | 3-5 | 1.5-6 | <=800 | 30 | 12-20 | 56 |

| 2400*20000 | 3-5 | 1.5-5 | <=800 | 37 | 18-30 | 60 |

| 3000*20000 | 3-5 | 1.5-5 | <=800 | 55 | 25-35 | 78 |

| 3000*25000 | 3-5 | 1.5-5 | <=800 | 75 | 32-40 | 104.9 |

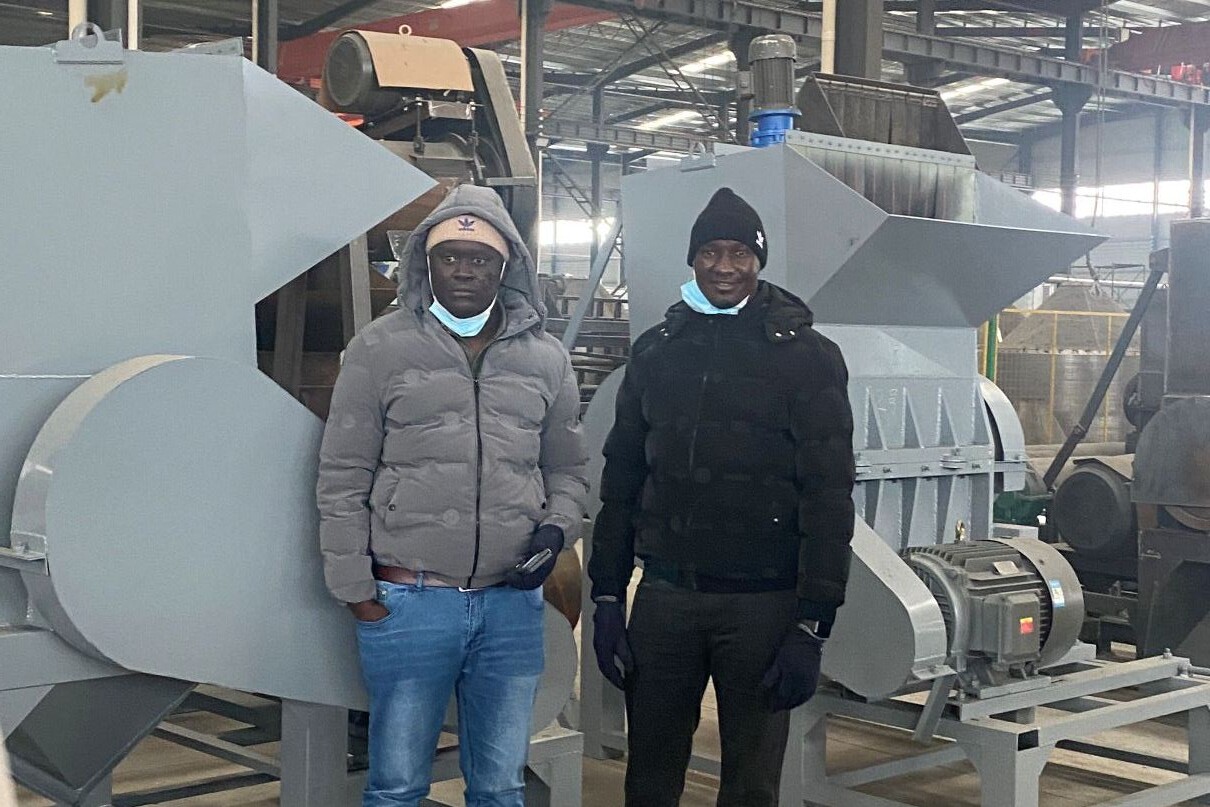

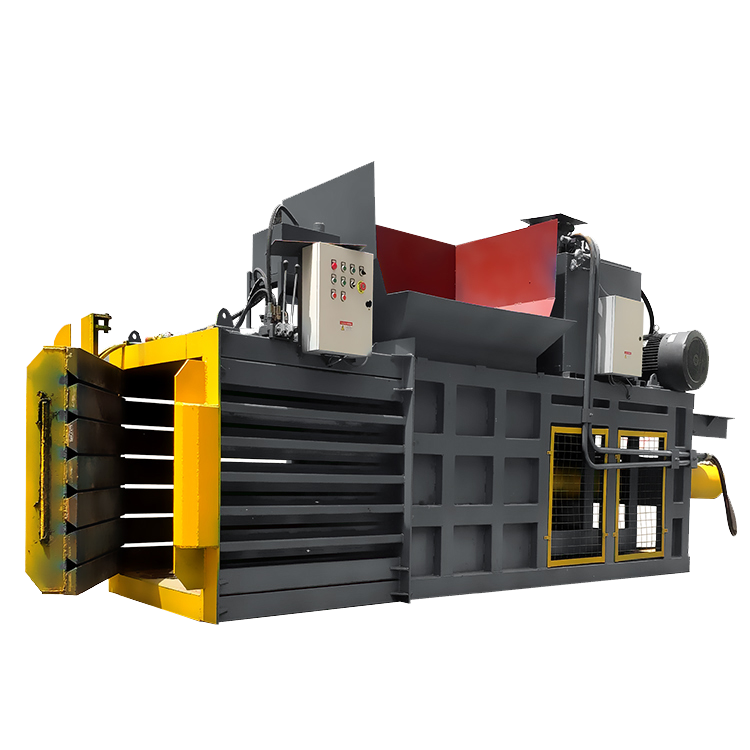

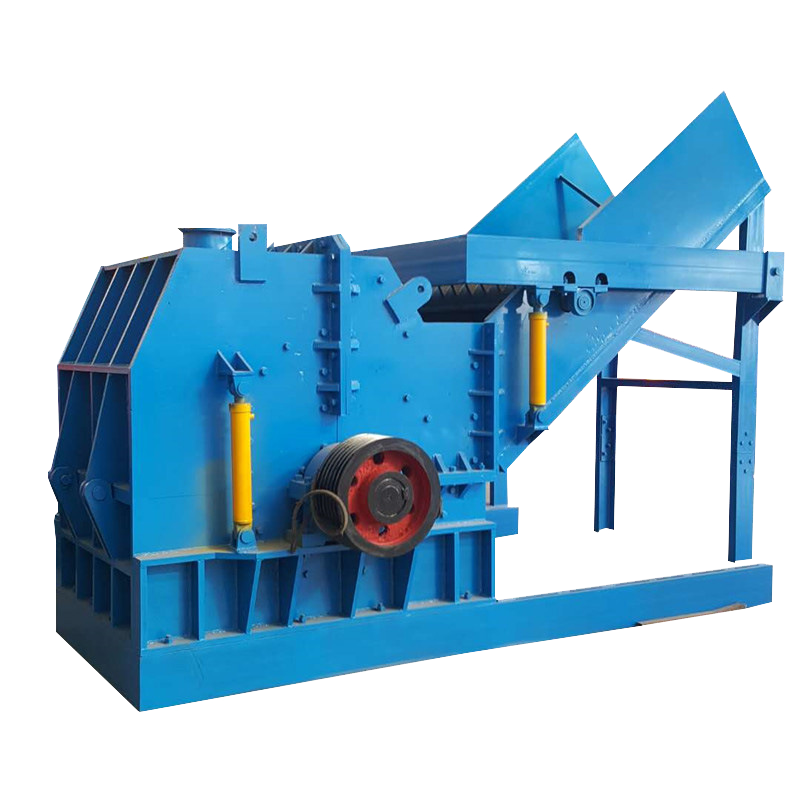

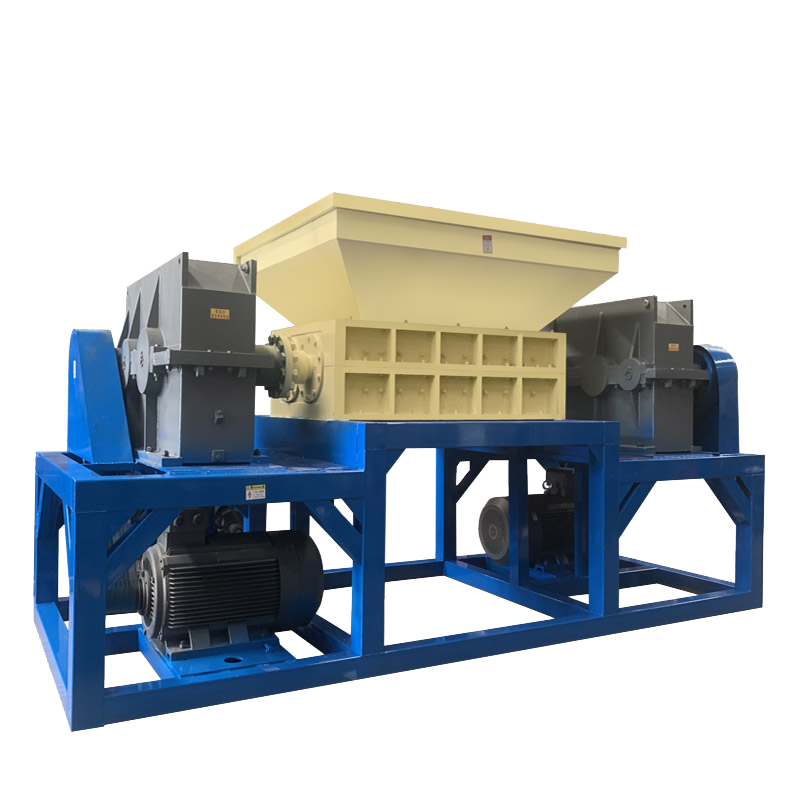

Industry Applications

Videos

Certification